Constructing a Roof Over Lawn Bowling Greens: A Quick Guide

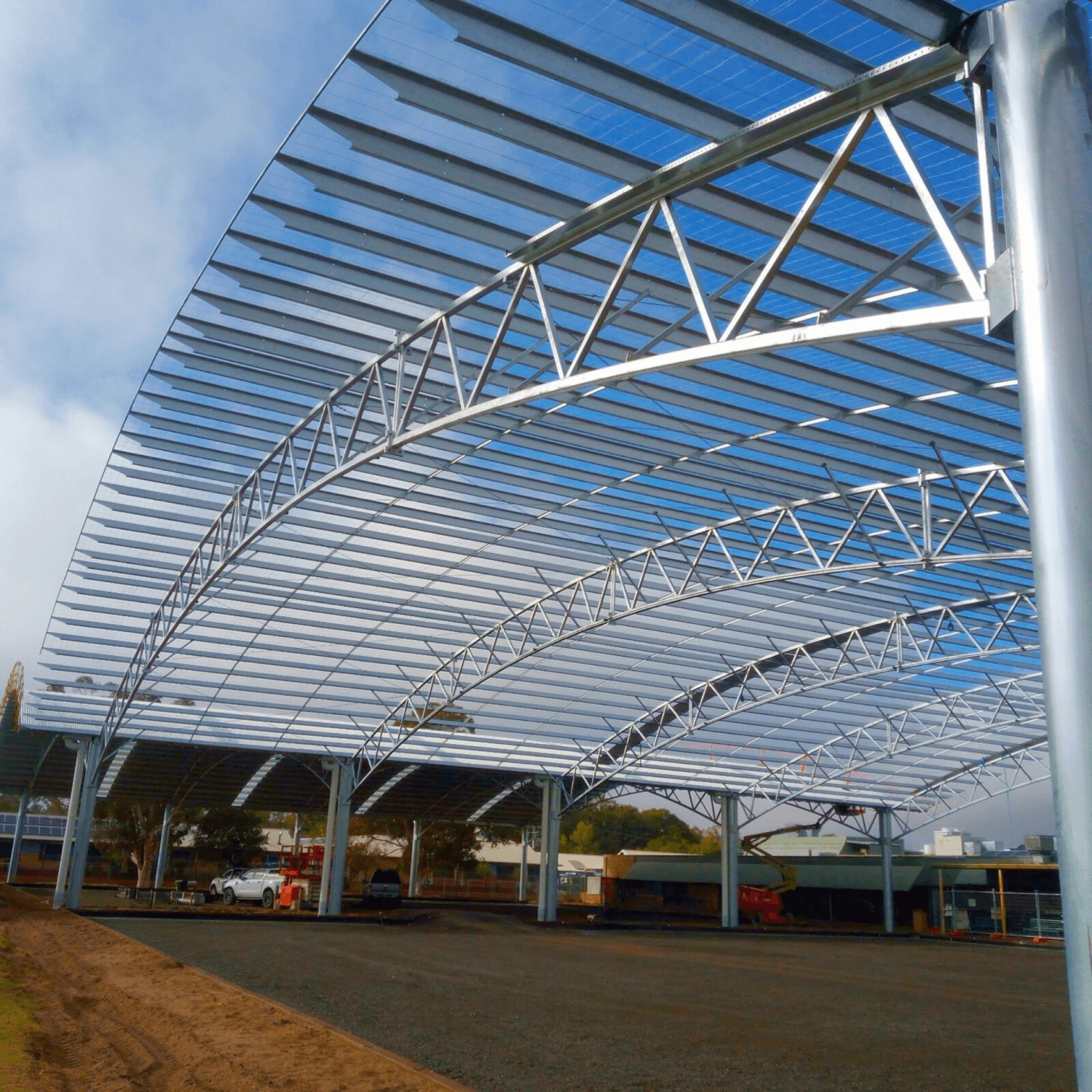

At Enviroclass, we specialise in delivering high-quality shade structure solutions for various outdoor activities such as lawn bowls. Lawn bowling is a beloved outdoor sport enjoyed by many, and providing a covered space can greatly enhance the experience for players and spectators alike. In this guide, we explore the process of constructing a roof over lawn bowling greens, and key considerations such as site access, sequencing of work, and protecting the green during the construction process.

Site Access and Layout:

Accessibility by Machinery: Prior to the installation of the green, it is crucial to ensure that the construction machinery can reach the site. This allows for a smoother and more efficient build. The amount of machinery accessibility directly affects critical items: cost and time.

Site Layout: The layout of the site plays a significant role in determining the construction methodology. Proper planning and consultation with engineers and suppliers are necessary to optimise the site's accessibility and functionality. Examples of what is considered for layout are things like hardstand working areas nearby, adjacent buildings or fixtures; this directly affects the orientation and configuration of the building and structural footings.

A Typical Construction Sequence:

- Footings: The initial step involves excavating and pouring the footings, providing a stable foundation for the structure.

- Structural Rigging: Once the footings are in place, the structural framework is erected. This includes the installation of columns, beams, and other load-bearing components.

- Roofing: The roofing materials are then installed, ensuring a durable and weather-resistant covering over the lawn bowling greens.

- Gutters, Flashing, and Rainwater Goods: To manage rainwater runoff effectively, the installation of gutters, flashing, and rainwater goods is essential.

Services Works:

Connection to Stormwater: Proper drainage is vital for maintaining the integrity of the synthetic bowling greens. Our team will ensure that the structure is connected to the existing stormwater system.

Wiring and Electrical Connection: If lighting is required, wiring and electrical connections will be installed to provide illumination for evening or indoor games.

Other Services Work: Depending on the specific project requirements, additional services work may be necessary, such as water supply, solar array or other utility connections.

Protecting the Green During Construction:

In some cases, the lawn bowling green may need protection during the construction process. Here are some steps we take to ensure its preservation:

Consultation: We collaborate closely with suppliers, installers, and engineers involved in the existing surface to understand the load limits and unique characteristics of the green.

Methodology and Load Limits: Our team will devise a methodology that adheres to the maximum load limits of the green, taking into account the specific requirements of the machinery and access needs for the project - as outlined in the ‘site access and layout’ section.

Green Protection Methods: Based on the agreed-upon method, we implement a protection system for the green. Some examples include:

- Laying Hessian: Covering the surface with hessian and bringing in a road base to provide a stable surface for machinery.

- Plywood or Similar Boards: Spreading plywood or similar boards on the green's surface to distribute load and prevent damage from wheels.

- Purpose Manufactured Systems: Utilising purpose-built systems, such as heavy-duty platforms, designed to withstand heavy traffic and protect the green.

Ideal Scenario:

To simplify the construction process, the ideal scenario is to build the structure before installing the green. This approach allows unrestricted access to machinery and ensures a seamless build.

The Wash up:

Constructing a roof over lawn bowling greens requires careful planning, consideration of site access, and adherence to load limits. By workshopping and following a proven sequence of works and implementing suitable protection methods, Enviroclass ensures the successful completion of projects, delivering exceptional steel-framed buildings tailored to unique requirements. Contact us today to discuss your project and discover how we can help transform your outdoor space into a comfortable and shaded environment for lawn bowling and other activities.

OVERVIEW

- Site access

- Construction sequence

- Services work

- Protecting the green

Share this

You May Also Like

These Related Stories

How to Build a Cover Over Existing Sports Courts

The Importance of Design in Design and Construct

.jpg)